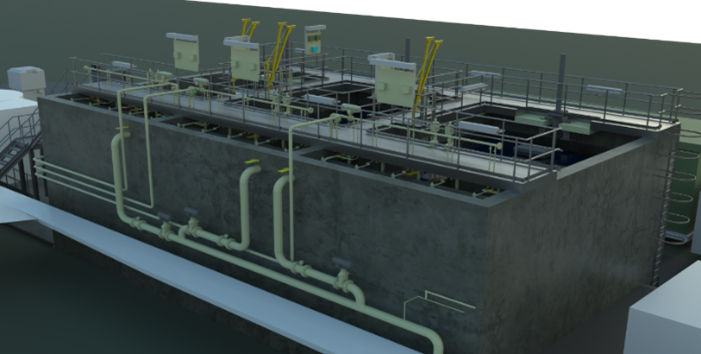

Like its sister plant, La Farfana, Mapacho-Trebal STW in Chile is owned by Aguas Andidas and operated by Edam. It also treats the sewage from a population of 3.7m with a design dry weather flow of 760Ml/d. The works is constructed in two zones. The Trebal zone (the first zone to be constructed) has eight conventional plug flow aeration lanes each with four air flow control valves. Air is supplied by four turbo blowers. The later Mapocho zone has eight plug flow and carrousel reactors with three air flow control valves per reactor. Air is supplied by two sets of three turbo blowers. As at La Farfana, the aeration blowers were originally controlled to a fixed pressure set point in the main air manifold and a fixed dissolved oxygen set point in the aeration lanes.

Plans for Self Sufficient STWs

Aguas Andidas has a medium term objective to transform their sewage treatment plants into self-sufficient biorefineries, by reducing energy consumption and recovering energy from waste sludge by anaerobic digestion. The main energy consumer at Mapocho-Trebal, like all activated sludge plants, was the aeration blowers, so control of aeration was the first step in energy reduction.

Intelligent Control of Aeration

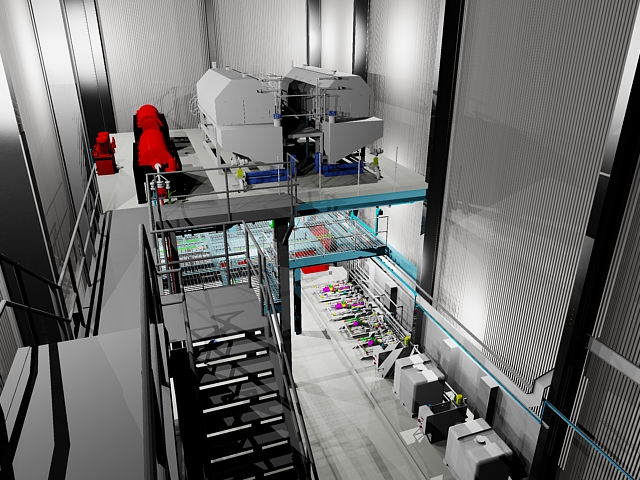

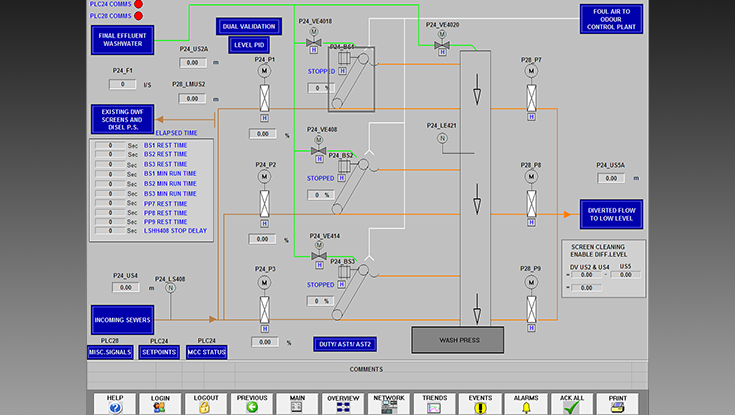

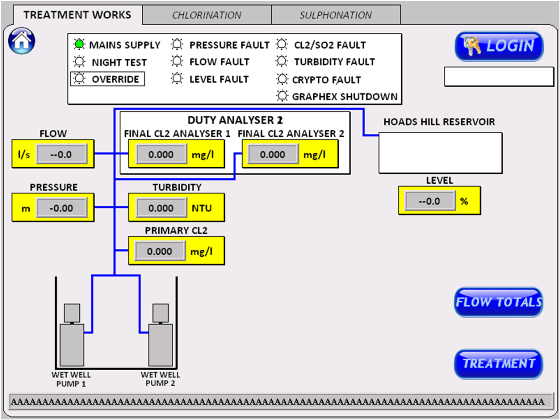

Following the success of the CREAPro® intelligent control system at La Farfana, Edam decided to use the same platform at Mapocho-Trebal to provide control of aeration. In addition to the existing air pressure and dissolved oxygen probes, a new final effluent monitoring centre was installed downstream of the final settlement tanks with probes for turbidity, COD, nitrate and suspended solids. These provide real time information to two software modules: C-CONTROL and MOV-CONTROL.

The inputs to the C-CONTROL module are works flow, final effluent COD, turbidity and nitrates, and DO in each reactor. It outputs independent and dynamic DO set-points for each reactor and sets aeration and anoxic phases with frequency and duration controlled depending on the raw sewage flow and the global performance of the whole biological treatment process. At low effluent COD, the system applies sequential anoxic phases in each reactor to decrease the energy demand.

The MOV-CONTROL provides a strategy that guarantees oxygen levels by applying dynamic pressure control in the main manifold, ensuring the maximum aeration system efficiency in terms of performance and energy consumption. It also limits flushing, which is only applied when a valve has not reached the target range of the opening degree/airflow in 24h.

Plant Upgrade Features

✔ CREAPro® intelligent control system

✔ C-Control & MOV-Control modules

✔ New Final Effluent Monitoring Centre

Aeration Energy Savings

Since installing the CREAPro® system, aeration energy consumption has been reduced by 17%, saving 4.8GWh in the first year of operation, and the final effluent quality has consistently met the discharge consent. Jordi Fontana, General Manager for Edam, is pleased with the result. “In large plants such as Mapocho-Trebal and La Farfana, the investment in this type of technology presents very short payback periods which make them highly recommended.”

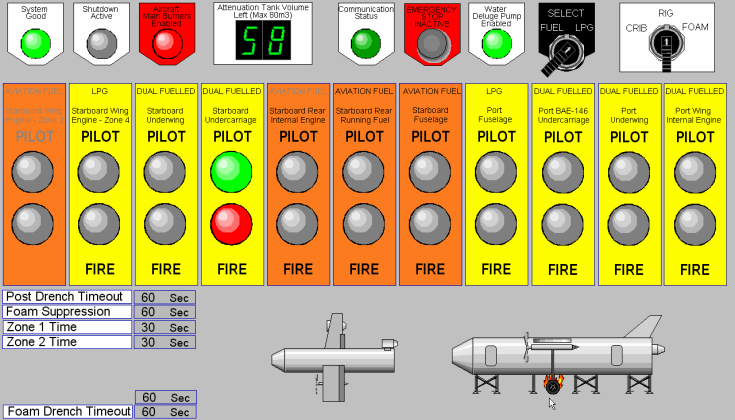

Intelligent control solutions in the UK

Te-Tech Process Solutions offers the CREA® intelligent platform to key clients within the UK water industry as part of our Asset Optimisation service, which includes total in-house capability from FDS to panel design and manufacture, including systems integration for both new and legacy STWs.

Contact Us for more information or to talk about your requirements email enquiries@te-tech.co.uk

|

Aeration energy reduced by 17% |

4.8GWh of electricity saved in the first year |

|

Full compliance with discharge consent |

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)

.png)