La Farfana STW is owned by Aguas Andidas and operated by EDAM. It treats about half of the sewage produced by the Greater Santiago conurbation, with a design dry weather flow of 617,000m3/day (population equivalent of 3.7 million).

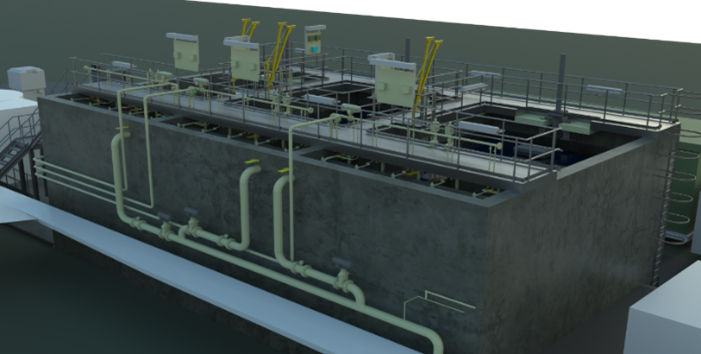

The works is a conventional activated sludge plant consisting of screening, grit removal, primary settling, biological treatment and final settlement with chlorination prior to discharge. There are 16 Primary Settling Tanks each 20m x 65m x 4m deep, 16 plug flow aeration lanes each of 11,000m3 and 16 final settling tanks each 50m diameter. The aeration blowers were originally controlled to a fixed pressure set point in the main air manifold and a fixed dissolved oxygen set point in the aeration lanes. The plant performance is summarised in the table to the right

Target: Working towards self-sufficient STWs

Aguas Andidas’ objective is to transform their sewage treatment plants into self-sufficient biorefineries by reducing energy consumption and recovering energy from waste sludge by anaerobic digestion. The main energy consumer at La Farfana, like all activated sludge plants, was the aeration blowers, so control of aeration was the first step in energy reduction. EDAM decided to install a new aeration control system powered by CREAPro® intelligent software.

Phase 1: Real-time data collection

As part of the upgrade, Createch360 installed a new effluent monitoring centre downstream of the final settlement tanks with probes providing real-time information on turbidity, COD, nitrate and suspended solids, in addition to the data from the existing air pressure and dissolved oxygen probes.

Phase 2: Continuous optimisation

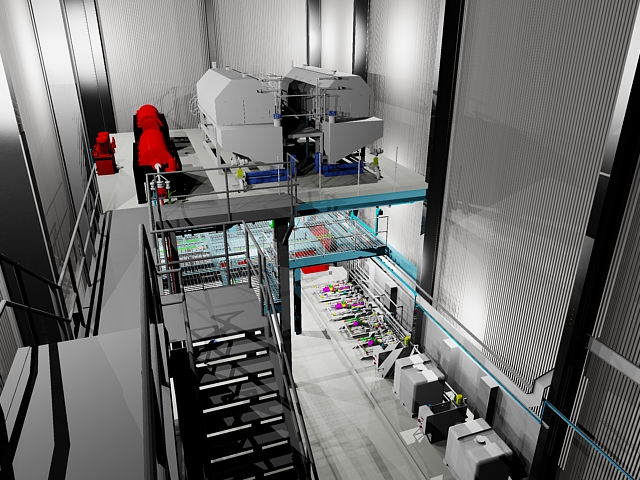

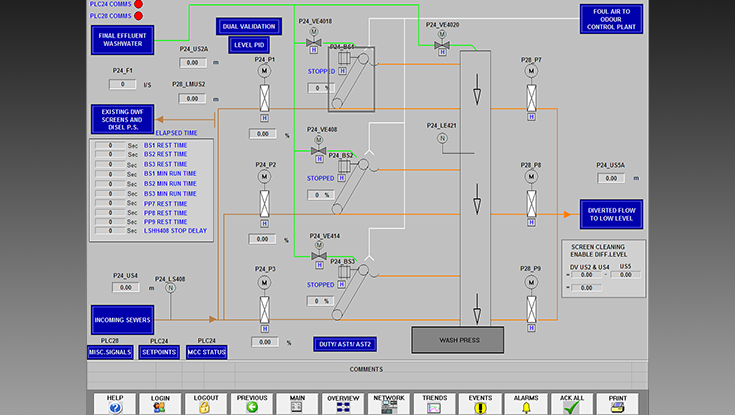

The real-time information is fed into two CREAPro® software modules: C-CONTROL and MOV-CONTROL. The inputs to the C-CONTROL module are works flow, final effluent COD, turbidity and nitrates, and DO in each reactor. It outputs independent and dynamic DO set-points for each reactor and sets aeration and anoxic phases with frequency and duration controlled depending on the raw sewage flow and the global performance of the whole biological treatment process. At low effluent COD the system applies sequential anoxic phases in each reactor to decrease the energy demand.

The MOV-CONTROL provides a strategy that guarantees oxygen levels by applying dynamic pressure control in the main manifold, ensuring the maximum aeration system efficiency in terms of performance and energy consumption. It also limits flushing, which is only applied when a valve has not reached the target range of the opening degree/airflow in 24h.

Results

Since installing the CREAPro® system, aeration energy consumption has been reduced by 18%, saving 15MWh/day, and the final effluent quality has consistently met the discharge consent. Jordi Fontana, General Manager for EDAM, is pleased with the result. “The implementation of the intelligent aeration control system in La Farfana, has been advantageous for EDAM not only in terms of a significant saving in energy consumption for aeration, but also for the plant supervision tasks. The intelligent control platform facilitates online control of the performance of the biological process as well as the quality of the effluent” he says.

Intelligent control solutions in the UK

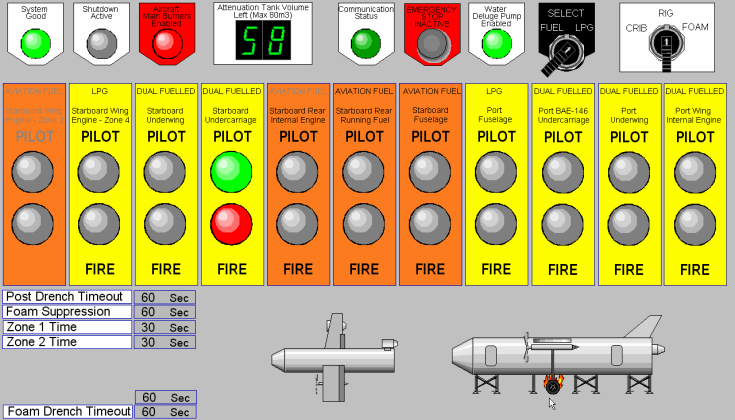

Te-Tech’s extensive capabilities in MCC, control panels, system integration is strengthen by our relationship with CREA@ for the design and implementation of artificial intelligence solutions

Te-Tech’s experienced team of electrical, control, software and process engineers specialise in integrating designs with the full capability to deliver complete process solutions, from panel design & manufacture, Systems Integration software and CREA® intelligent software into both new and legacy systems.

Contact Us for more information or to talk about your requirements email enquiries@te-tech.co.uk

|

Aeration energy consumption has been reduced by 18% |

Cost saving 15MWh/day |

|

Intelligent control platform facilitates online control |

Final effluent quality has consistently met the discharge consent |

Plant Performance

| Raw | FE | Consent | |

| BOD (mg/l) | 200 | 6 | 35 |

| COD (mg/l) | 457 | 57 | 125 |

| SS (mg/l) | 224 | 12 | 35 |

| TKN (mg/l) | 60 | 32 | |

| TP (mg/l) | 13 | 7 |

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)

.png)