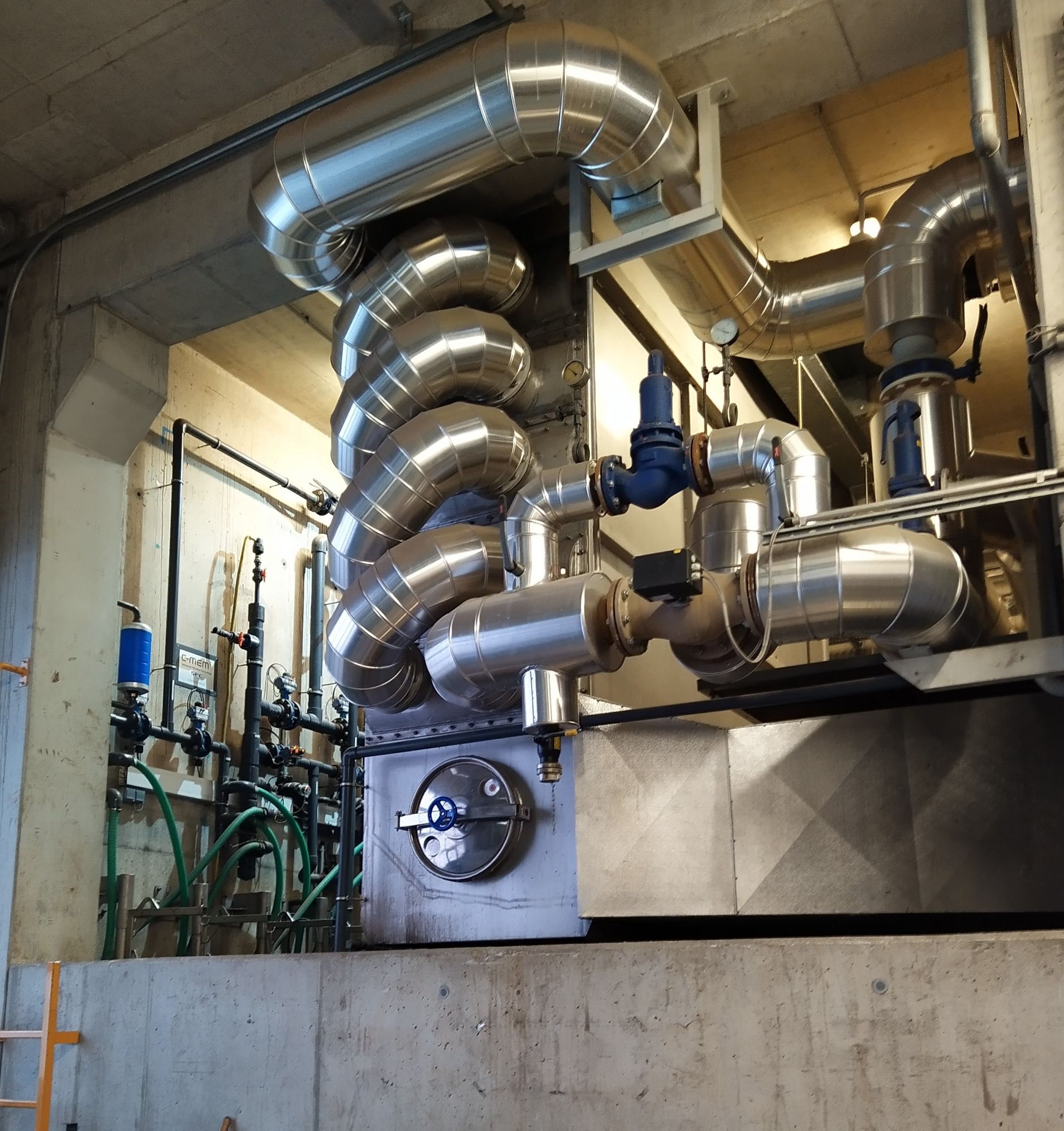

Te-Tech Process Solutions can provide effective treatment of the condensate generated from the heat recovery systems in biomass energy plants, through the application of te-memTM submerged membrane ultrafiltration.

Biomass is established as a viable and sustainable fuel source for the generation of electricity and heating. The reliance on a humid combustible material is not however always efficient, prompting the adoption of heat recovery from the flue gases.

te-memTM is a particularly effective process for the treatment of the aqueous stream generated from the condensate which is high in turbidity, colour, COD and ammonia levels but with a low BOD:COD ratio and poor biodegradability.

The te-memTM process uses hollow fibre membranes wrapped around a carrier inside a cartridge and arranged in bundles. The cartridge provides the required strength and protection for the hollow fibres which operate in an outside-in configuration, allowing the application of high-pressure air scouring, the most efficient membrane cleaning method. The cartridges are combined into modules with common permeate and air scour connections.

The hydrophilic membranes have an average pore size of 20nm, giving high rejection of particulate suspended solids, organics, bacteria and viruses. Clean water fluxes up to 300 lmh are possible with trans-membrane pressures in the range 50 - 600mbar. The membrane is robust, chemical-resistant and suitable for the high temperatures in a thermal power station. During breaks in operation, the membrane can be dried out and returned to service without pre-treatment.

The pore size of the membranes allows for the removal of bacteria and viruses. Its compact design makes the modules suitable for condensate streams, grey water / water re-use, as well as conventional water and wastewater treatment applications with a number of key benefits.

- Compact – High packing density provides a small footprint

- Simple – Easy operation, access and maintenance

- Performance – Robust fibres with anti-fouling properties and effective air scour cleaning system

- Resilient – Hollow fibres highly resistant to oxidative chemicals protected in a strong cartridge design

- Cost Effective – Ease of operation and low energy demand

- Flexible – Individual simple cartridge replacement

- Versatile – Submerged arrangement avoids external pipework

Te-Tech Process Solutions are excited to bring te-memTM membrane technology to the UK market after numerous successful installations across Europe and the UK.

.png)

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)