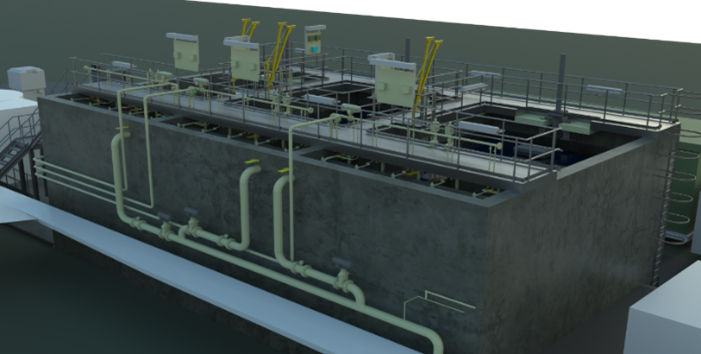

The municipal sewage treatment plant at Lodz in Poland serves a population of a million with a design flow of 215.3Ml/d. The process consists of seven plug flow aeration lanes for nitrification and anoxic zones for biological nutrient removal. Aeration is provided by five 630kW turbo blowers with four flow control valves in each aeration lane controlled by air main pressure. Instrumentation in each lane consists of an inlet flow meter, four dissolved oxygen monitors, nitrate analysers at the anoxic zone outlet and bioreactor outlet, MLSS in the bioreactor and final effluent turbidity.

Targeting Reduced Aeration Costs

The plant operator wanted to reduce the aeration energy consumption whilst ensuring compliance with the discharge consent.

Meeting the Nitrogen Consent

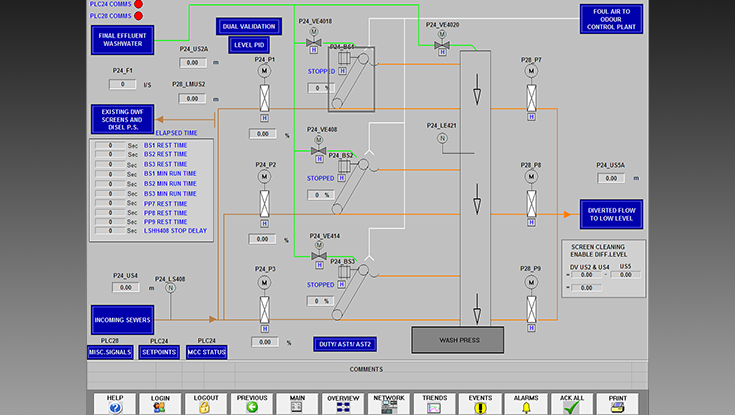

A new control system using the CREA® intelligent platform was installed, with the MOV-Control, N-Control, iRAS-Control AI modules together with Intelligent Data Management (IDM) which checks signal reliability and diagnoses probe problems. The MOV-Control and N-Control modules take inputs from the ammonia, nitrate, dissolved oxygen and final effluent turbidity analysers together with the energy price tariff. The module calculates a dynamic set point for dissolved oxygen to achieve the effluent quality requirements and sets a working frequency and performance for the aeration blowers. It sets anoxic cycle durations to achieve nitrification based on the nitrogen removal rate. Further, it takes into account variation in the electricity price tariff to reduce energy consumption peaks based on a 24-hour average final effluent nitrogen concentration. The iRAS-Control module optimises sludge recirculation in real time based on nitrate concentration at the anoxic zone outlet and at the bioreactor outlet.

Significant Energy Savings

Since the implementation of the CREA® intelligent control system, pumping energy consumption has been reduced by 20% as well as aeration energy by 20%, with final effluent in full compliance with the discharge consent.

New Modules Installed

✔ N-Control, MOV-Control and iRAS-Control

✔ Intelligent Data Management (IDM)

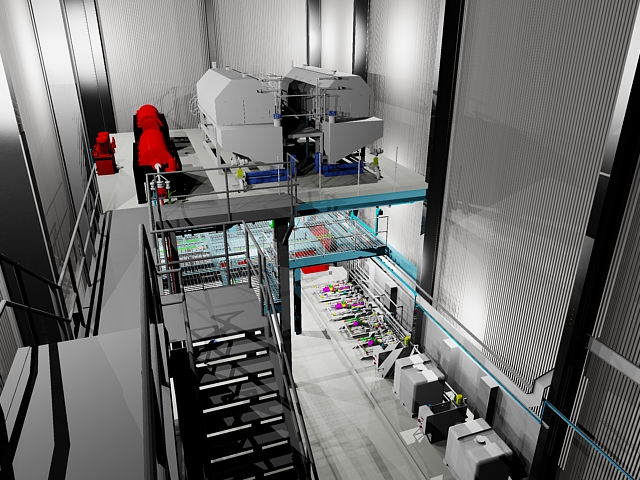

Intelligent control solutions in the UK

Te-Tech’s extensive capabilities in MCC, control panels, system integration is strengthen by our relationship with CREA@ for the design and implementation of artificial intelligence solutions

Te-Tech’s experienced team of electrical, control, software and process engineers specialise in integrating designs with the full capability to deliver complete process solutions, from panel design & manufacture, Systems Integration software and CREA® intelligent software into both new and legacy systems.

Contact Us for more information or to talk about your requirements email enquiries@te-tech.co.uk

|

20% reduction in aeration energy consumption |

20% reduction in pumping energy consumption |

|

Overall site energy savings of 17% |

Full compliance with discharge consent |

Plant Performance

| Consent | |

| BOD (mg/l) | <15 |

| TSS (mg/l) | <35 |

| Ammoniacal nitrogen (mg/N/l) | <10 |

| Nitrate nitrogen (mg/N/l) | <30 |

| Total nitrogen (mg/N/l) | <10 (annual average) |

| Total phosphorus (mg/P/l) | <1 (annual average) |

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)

.png)