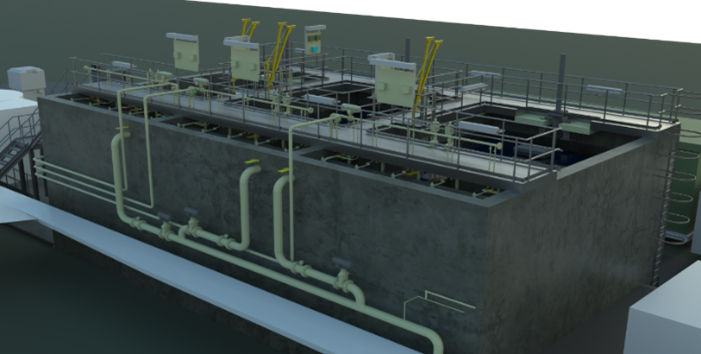

The municipal sewage treatment plant at Brembate in Italy serves a population of 185,000 with a design flow of 53.6Ml/d. The plant has two plug flow aeration lanes for nitrification and anoxic zones for biological nutrient removal each supplied with air from a 110kW turbo blowers. Instrumentation consists of dissolved oxygen monitors in each aeration lane and ammonia and nitrate analysers for the final effluent.

Energy Reduction Goal

The plant operator, Hidrogest S.p.a, wanted to reduce energy consumption whilst ensuring compliance with the discharge consent. The discharge consent is summarised in the table to the right.

Meeting the Nitrogen Consent

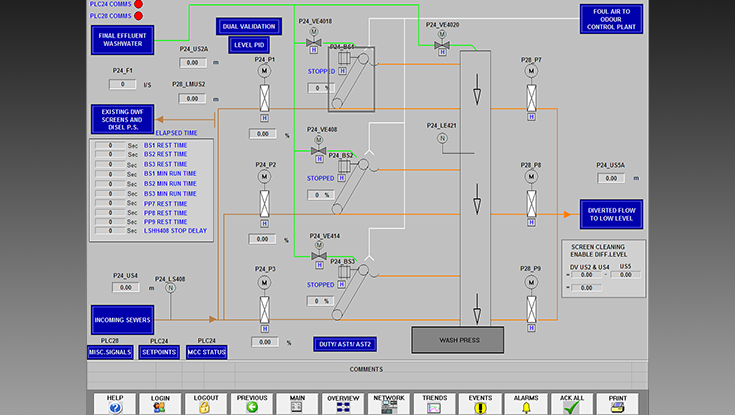

A new control system was installed; the CREA® intelligent platform, with a module for N-Control. This module takes inputs from the ammonia, nitrate and dissolved oxygen analysers and calculates a dynamic set point for dissolved oxygen to achieve the effluent quality requirements and sets a working frequency and performance for the aeration blowers. It sets anoxic cycle durations to achieve nitrification based on the nitrogen removal rate.

Results

Since the implementation of the CREA® intelligent control system, overall plant energy consumption has been reduced by 13% and aeration energy by 25% with final effluent in full compliance with the discharge consent. The plant’s emission of greenhouse gases has also been reduced by 34 to 26 teCO2/month.

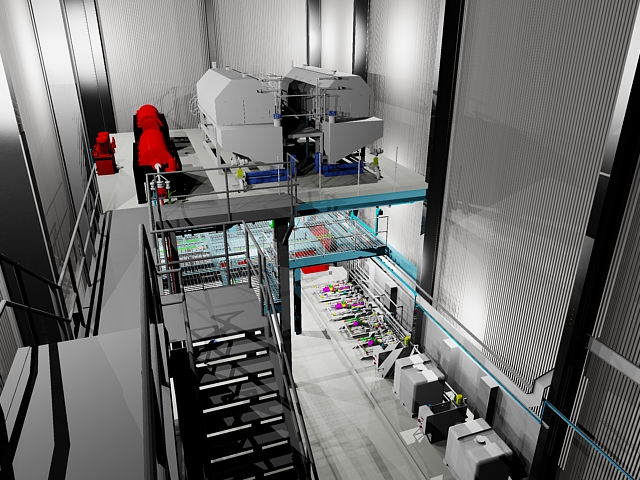

Intelligent control solutions in the UK

Under a new licence agreement, Te-Tech Process Solutions is able to offer CREA® intelligent software to key clients within the UK water industry. Combining this state-of-the-art software with their own advanced technologies and products for the wastewater sector. Te-Tech is able to provide total in-house capability from FDS to panel design and manufacture, including systems integration for both new and legacy wastewater treatment plants.

Find out more about Nutrient Removal

Contact Us for more information or to talk about your requirements email enquiries@te-tech.co.uk

|

13% reduction in overall plant energy consumption |

25% reduction in aeration energy requirements |

|

24% reduction in greenhouse gas emissions |

100% effluent quality compliance |

Plant Performance

| Consent | |

| BOD (mg/l) | |

| TSS (mg/l) | |

| Ammoniacal nitrogen (mg/N/l) | |

| Total nitrogen (mg/N/l) | |

| Total phosphorus (mg/P/l) |

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)

.png)