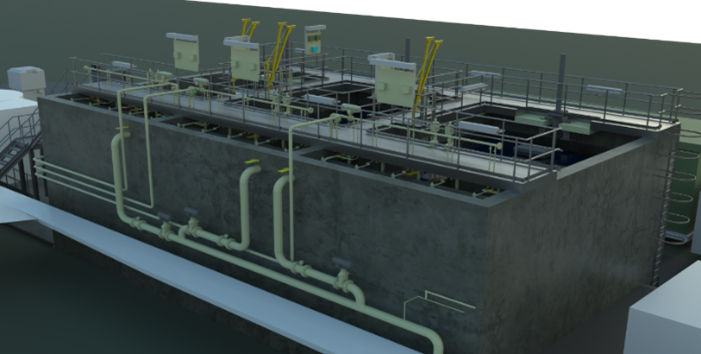

The municipal wastewater treatment plant at Manresa in North East Spain was designed for a flow rate of 53.5Ml/d. The works normally operates at about 50% hydraulic capacity with a phosphorus load of 170kg/day. It consists of two plug flow lanes for biological nitrogen removal with ferric chloride dosing for phosphorus precipitation to meet the 1mgP/l discharge consent, and/or polyaluminium chloride dosing to assist in secondary sludge settlement depending on the time of year.

Outdated manual dosing

Originally, the dosing was controlled manually at a fixed dose rate. This led to overdosing for some of the time but underdosing at peak phosphorus loads. The result was excessive chemical use and no assurance that compliance with the discharge could be achieved consistently. To better ensure effluent quality, optimize chemical dosing and reduce reagents costs, Aigüesde Manresa decided to install a CREA® intelligent control system.

Installation of CREA® and new Phosphate Analyser

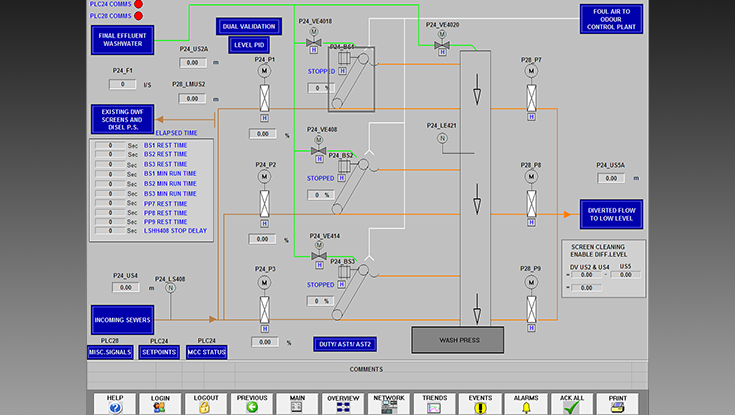

A new control system was installed; the CREA® intelligent platform, with AI modules for denitrification (N-Control), chemical precipitation (P-Control), aeration optimisation (MOV-Control) and sludge recycling (RASi-Control). As well as utilising existing instrumentation, they also added a new phosphate analyser located downstream of the final settling tanks to control the chemical dosing.

Results

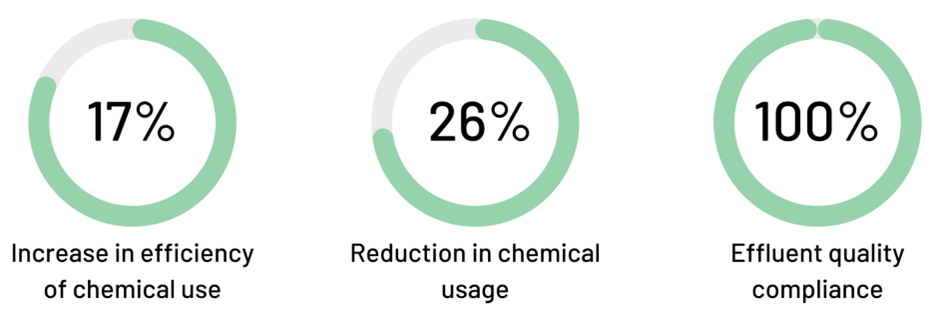

Continuously optimising the process performance ensures that treated effluent quality is always met, and it also means that the plant uses fewer resources, reducing carbon footprint. Since installing the CREA® system, the Manresa works has improved the efficiency of chemical utilisation by 17% from 8.7kg/kgP in 2020 to 7.3kg/kgP in 2021. This has reduced the overall chemical consumption by 26% in the same period.

Intelligent control solutions in the UK

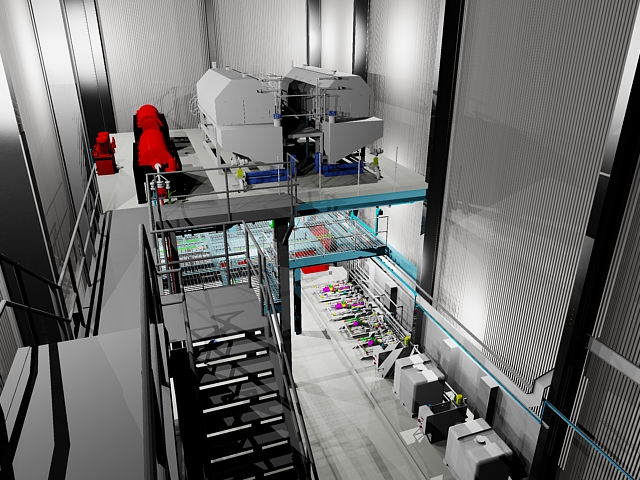

Te-Tech’s extensive capabilities in MCC, control panels, system integration is strengthen by our relationship with CREA@ for the design and implementation of artificial intelligence solutions

Te-Tech’s experienced team of electrical, control, software and process engineers specialise in integrating designs with the full capability to deliver complete process solutions, from panel design & manufacture, Systems Integration software and CREA® intelligent software into both new and legacy systems.

Contact Us for more information or to talk about your requirements email enquiries@te-tech.co.uk

Plant Upgrade Features

✔ CREA® intelligent control platform

✔ N-Control, MOV-Control and SRT-Control modules

✔ New Phosphate Analyser

✔ Flow rate 53.5 Ml/d

✔ CREA® reduces chemical usage

✔ CREA® ensures effluent quality

%20-%20Wastewater%20from%20Biomass%20Heating%20Plant%201.png)

.png)