Introduction

Phosphorus is a naturally occurring nutrient for life and essential for all living organisms. Phosphates and Nitrates promote plant growth and are therefore commonly used in fertilisers, but can also be found in detergents, food residues and subsequent animal and human waste.

Excessive amounts of nutrients in water bodies can however lead to eutrophication creating toxic and anoxic conditions that are fatal or harmful to fish and other aquatic life.

All stakeholders have a duty to protect and enhance the natural environment and to meet increasingly stringent discharge consent standards as part of a combined treatment and catchment based approach to regulation.

Te-Tech can provide effective advanced wastewater treatment solutions for commercial clients seeking to achieve Nitrate Neutrality on new developments and for municipal and industrial clients who require enhanced biological Phosphorus removal to achieve tightening P consents.

- Phosphorus

- Eutrophication

- Regulation

- Phosphorus Removal

- Chemical Treatment

- Biological Treatment

- Te-Tech Process Solutions

- Modular Treatment Solutions

Phosphorus

Phosphorus is a naturally occurring nutrient for life and essential for all living organisms.

Phosphates and Nitrates promote plant growth and are therefore commonly used in fertilisers, but can also be found in detergents, food residues and subsequent animal and human waste.

Industrial and municipal wastewater treatment plants will have regulatory discharge consent obligations to satisfy prior to discharge into the receiving water body, however when nutrients are found in excessive amounts in the water body, this can still lead to eutrophication.

Eutrophication

Eutrophication is characterised by an increase in nutrient levels in a water body that promote algal growth, the algal blooms created impede sunlight which in turn leads to the algae dying off. Bacteria digest the dead plants and in so doing consume Oxygen and generate Carbon Dioxide, depleting the Oxygen levels in the water. This process creates toxic and anoxic conditions that are fatal or harmful to fish and other aquatic life.

The decomposition of the algae and other dead organic matter then converts the organic form of phosphorus into orthophosphate, making phosphate available once again for plant growth, continually perpetuating the eutrophication cycle.

Regulation

Acceptable Phosphorus discharge consent levels have become increasingly stringent over the years, enforced through progressive legislation, including the Urban Wastewater Treatment Directive and most recently, the Water Framework Directive targeting what is termed a ‘Good’ water quality status for identified river catchments.

Water companies have a duty to protect and enhance the natural environment, the Water Industry National Environment Programme (WINEP) sets out the actions that companies will need to complete to meet their environmental obligations.

The Environment Agency, through the Water Industry National Environment Programme have identified over 900 wastewater treatment plants where Phosphorus consents will come into force before 2025 ranging from Total Phosphorus levels of 2mg/l down to 0.01mg/l.

Phosphorus Removal

The removal of Phosphorus from wastewater can be achieved through biological or chemical removal processes, or a combination of both biological and chemical treatment. Treatment is increasingly considered as part of a wider catchment management programme where water companies may also engage with other stakeholders including the farming community.

Chemical Treatment Challenges

Chemical treatment uses a metal salt, typically iron, to precipitate ortho-phosphate. The precipitate generates solids that can then be captured in a downstream solids removal process, such as a settlement tank or tertiary solids removal stage.

Chemical Dosing

Over a period of 10 years, the number of sites with a P consents has increased from 200 to 800, the corresponding increase in Ferric dosing expected will exceed the current manufacturing capacity. This increase in chemical consumption is not only driven by an increase in the number of sites with a prescribed P consent, but also lower target P consents demanding higher relative metal iron doses. This increase in chemical demand will place extreme pressure on the availability and price of Ferric salts in the future.

The introduction of P consents on small and rural sites impose an additional operational burden on water companies. In addition to the capital cost of infrastructure to receive bulk chemical deliveries and the associated storage and dosing equipment, greater demand is placed on existing operators to maintain and service the assets coupled with the associated health and safety considerations at remote sites.

Sludge Production

The increase in chemical dosing and precipitation will have a corresponding increase in the generation of wastewater sludge, requiring the upgrade of sludge treatment assets and the ongoing operational cost of sludge treatment and disposal.

Residual Iron Consents

Water companies are finding it increasingly challenging to satisfy both stringent P consents whilst still having to respect more stringent residual Fe consents, these are harder to satisfy as the chemical dosing increases to achieve the tight P consents.

Alkalinity

Increased dosing to achieve low P concentrations increases the propensity of excess metal salts in the wastewater, any excess salts will react and reduce the alkalinity of the wastewater. If the alkalinity of the wastewater is too low this will inhibit the ability of the process to effectively treat ammonia which may compromise and potentially result in a breach of any ammonia consent.

Biological Treatment

Enhanced biological phosphorus removal is achieved by promoting specific microorganisms in the water, which can absorb and store phosphorus as polyphosphate. The Phosphorus is stored in the biomass and separated from the treated water. Enhanced biological phosphorus removal provides key operational cost savings by reducing the reliance on chemical dosing to precipitate solids to capture the Phosphorus and a reduction in air demand and energy costs through an efficient use of oxygen in the biological process.

Te-Tech Process Solutions

Te-Tech Process Solutions are able to provide an efficient, sustainable and cost effective solution for biological Phosphorus removal, to achieve stringent P consents, as low as 0.3mg/l.

The te-cycTM process, with over 500 reference plants around the world, is at the forefront of biological phosphorus removal, an enhanced biological treatment process for effective nutrient removal and sludge stabilisation. te-cycTM is the ideal solution for commercial clients seeking to achieve Nitrate Neutrality on new developments and for municipal and industrial clients who require enhanced biological Phosphorus removal to achieve tightening P consents.

The te-cycTM process is a cyclic activated sludge process achieving simultaneous nitrification, denitrification and biological P removal. te-cycTM is an advancement on conventional wastewater treatment technologies providing enhanced treatment with low energy consumption and a small overall footprint compared to traditional activated sludge (AS), sequencing batch reactors (SBRs) or granular sludge processes.

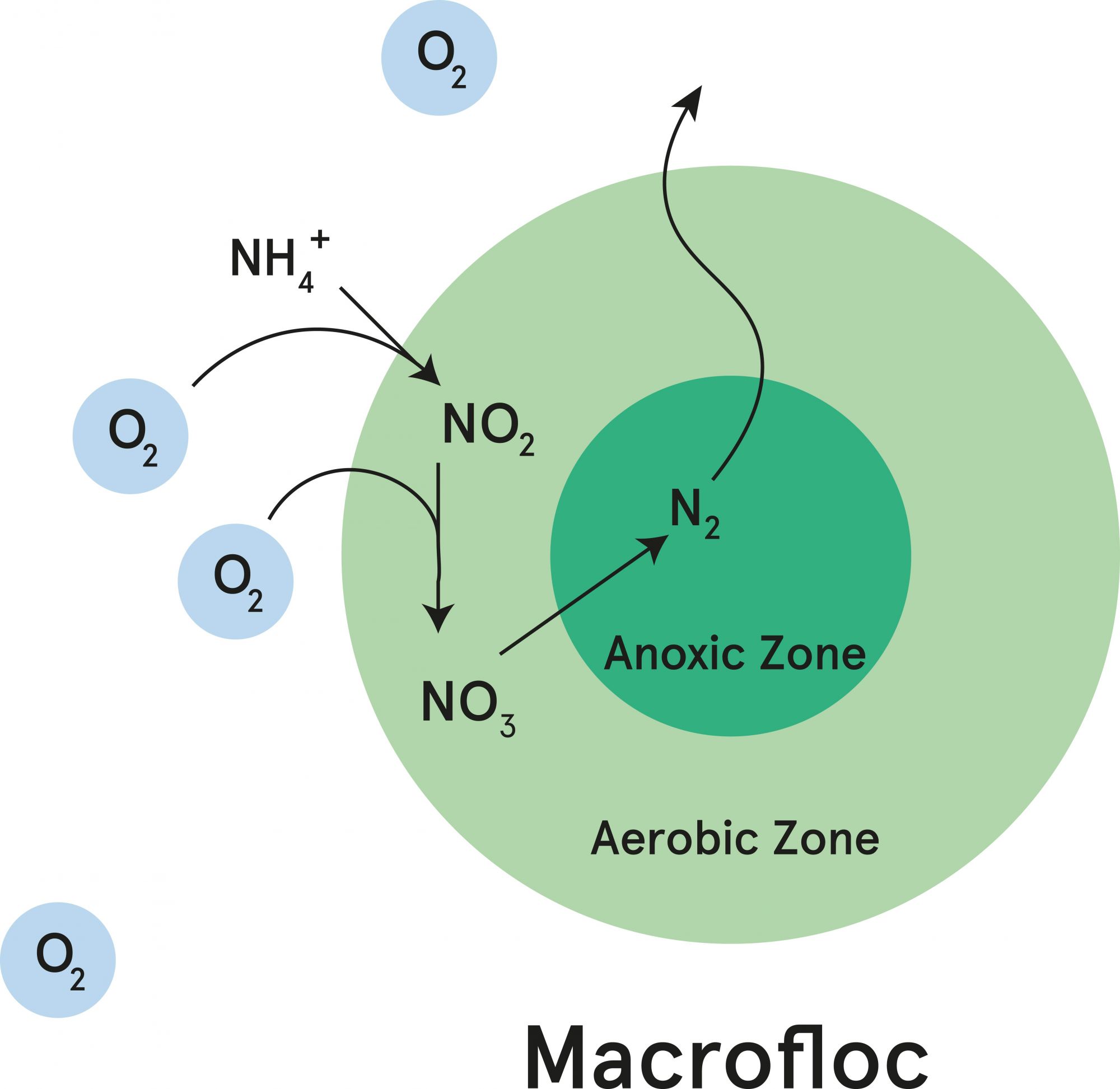

The te-cycTM process incorporates an anaerobic selector zone, which suppresses the growth of bacteria that cause sludge bulking and includes internal recycling of the biomass to the main reactor zone to create the formation of ‘macroflocs’.

In the te-cycTM configuration these larger macroflocs form an internal anoxic zone and external aerobic zone and contain polyphosphate accumulating organisms or PAO’s. On the macrofloc surface, bacteria act to convert ammonia to nitrate whilst the PAO's take up phosphorus from the surrounding liquid. Inside the macrofloc, anaerobic bacteria convert the nitrate to nitrogen gas, which escapes harmlessly to atmosphere.

These macroflocs promote enhanced biological phosphorus removal and very low sludge volume indices and the simultaneous carbon oxidation and nitrification / denitrification in one basin enables shorter cycle times and eliminates the need for a separate denitrification treatment stage. The te-cycTM process provides enhanced phosphorus removal to achieve more stringent phosphorus effluent values without the need for an additional solids removal treatment stage.

The te-cycTM process also incorporates advance process control by means of OUR (Oxygen Uptake Rate). The OUR real time control (RTC) system determines the time and intensity of aeration according to the degree of pollution in the wastewater, which results in economic operation of the plant and reduced operational costs.

The te-cycTM Technology is a simple low operational cost solution providing effective nutrient removal, enhanced biological treatment and sludge stabilisation for municipal, industrial and commercial wastewater treatment applications.

Modular Treatment Solutions

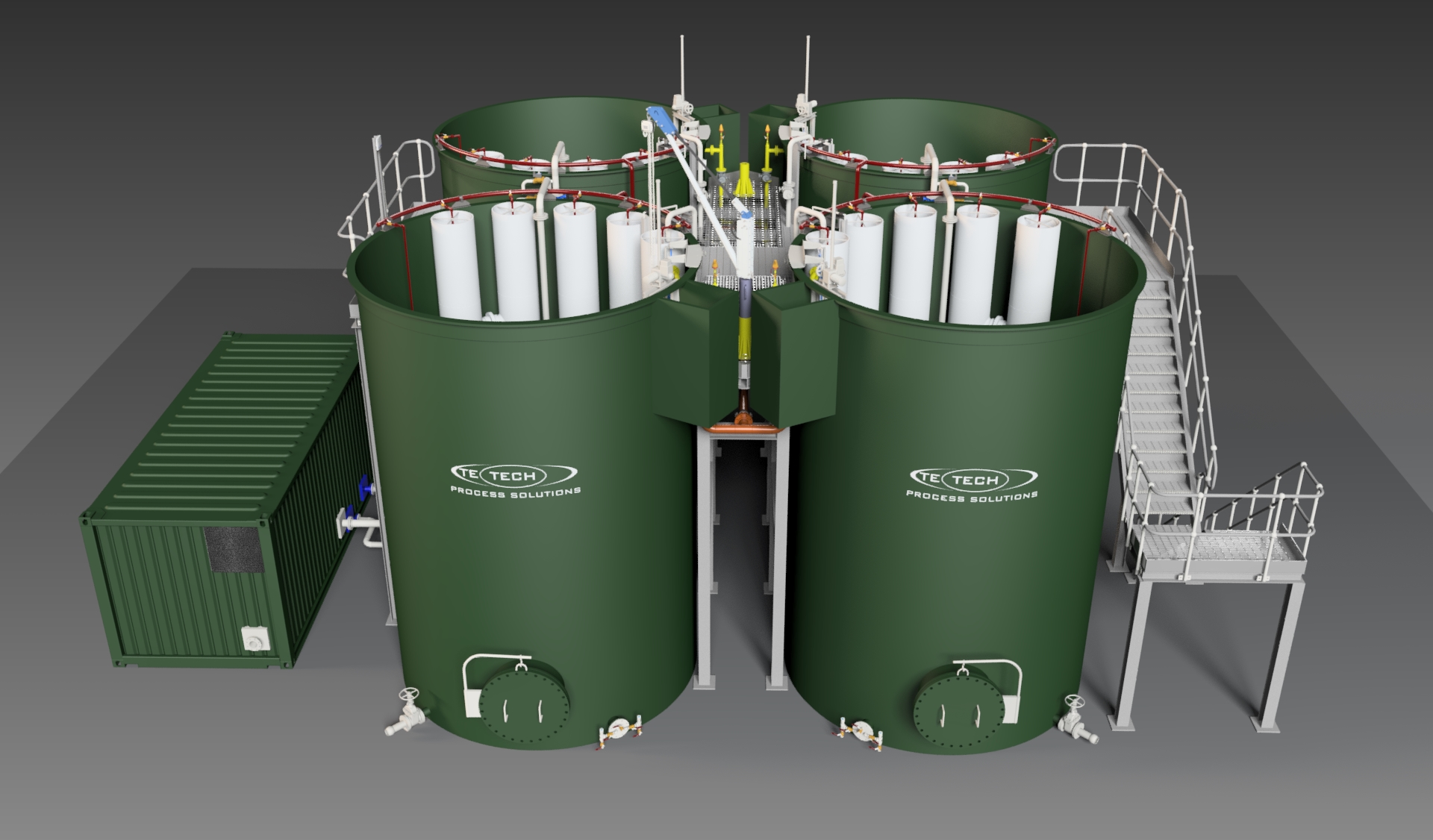

The te-cycTM process is a simple, efficient, low operational cost solution available as a bespoke design in concrete tanks or in a range of standard off site manufactured modular units to suit different sizes and applications.

The standard modular units come as a complete ‘plug and play’ system including aeration blowers, chemical dosing and local control panels for automated operation. If required Te-Tech can also provide a full end to end solution including inlet works and screening and any subsequent sludge storage, treatment or disposal stages.

Modular solutions for small to medium size developments can be provided as above or below ground installations where the aesthetic impact is a particular consideration.

Larger sites can be catered for with multiple units or streams particularly where there may be seasonal variations in flow and load or alternatively where operational flexibility is required or where flows may be phased or incremental as developments progress.

Te-Tech can also provide larger standard cylindrical modular units for higher flow rates which again can be provided in multiple streams for operational flexibility or phased flow and load increments.