Introduction

Te-Tech have been working with developers, engineers and consultants to provide an efficient solution to address the nitrate neutrality challenge.

Nutrient Neutrality, or Nitrate Neutrality as it is commonly called, has become a key obstacle for developers when seeking to obtain planning approval in counties that host areas protected under the Water Environment Regulations and Conservation of Habitats and Species Regulations. These protected areas may already experience high input levels of nitrogen and phosphorous into the water environment contributing to eutrophication at these designated sites.

This issue has been subject to detailed investigation commissioned by local planning authorities in association with Natural England, the Environment Agency and water companies. The real concern relates to the potential for future housing and developments with ‘overnight accommodation’ such as hotels and tourist attractions, to increase the impact on these protected habitats.

To address this issue, new developments must now satisfy strict requirements to demonstrate that they will achieve nutrient neutrality. Nitrate neutrality is the method of ensuring that any future development will not add to the existing nutrient load and will comply with requirements of the Conservation of Habitats and Species Regulations.

Achieving Nitrate Neutrality has not been a straightforward exercise for developers and is dependent upon a number of different and sometimes conflicting requirements with multiple stakeholders who often have different drivers and priorities.

-

Nitrogen and Phosphorus

- Eutrophication

- Regulation & Planning

- Calculating Nutrient Neutrality

- Mitigation

- Te-Tech Process Solutions

- Modular Treatment Solutions

Te-Tech Process Solutions can however assist developers in achieving Nitrate Neutrality through the provision of advanced on-site wastewater treatment systems as part of their overall Nitrate Neutrality solution.

Te-Tech can provide an effective advanced wastewater treatment solution for commercial clients seeking to achieve Nitrate Neutrality on new developments. Our te-cycTM technology is an advanced biological treatment process utilising cyclic activated sludge technology achieving simultaneous nitrification and denitrification for the effective removal of Nitrates and Phosphorus to meet ever tightening discharge consents.

Available as standard modular treatment units, the te-cycTM process can be located above or below ground depending upon the size of the development.

Nitrogen and Phosphorus

Nitrogen and phosphorus are naturally occurring nutrients for life and essential for all living organisms. Phosphates and Nitrates promote plant growth and are therefore commonly used in fertilisers, but can also be found in detergents, food residues and subsequent animal and human waste.

All stakeholders have a duty to protect and enhance the natural environment and to meet increasingly stringent discharge consent standards as part of a combined treatment and catchment based approach to regulation.

Industrial and municipal wastewater treatment plants will have regulatory discharge consent obligations to satisfy prior to discharge into the receiving water body, however when nutrients are found in excessive amounts in the water body, this can still lead to eutrophication creating toxic and anoxic conditions that are fatal or harmful to fish and other aquatic life.

Eutrophication

Eutrophication is characterised by an increase in nutrient levels in a water body that promote algal growth, the algal blooms created impede sunlight which in turn leads to the algae dying off. Bacteria digest the dead plants and in so doing consume Oxygen and generate Carbon Dioxide, depleting the Oxygen levels in the water. This process creates toxic and anoxic conditions that are fatal or harmful to fish and other aquatic life.

The decomposition of the algae and other dead organic matter then converts the organic form of phosphorus into orthophosphate, making phosphate available once again for plant growth, continually perpetuating the eutrophication cycle.

Regulation & Planning

Acceptable discharge consent levels have become increasingly stringent over the years, enforced through progressive legislation, including the Urban Wastewater Treatment Directive and most recently, the Water Framework Directive targeting what is termed a ‘Good’ water quality status for all identified river catchments.

Catchment areas that are already protected under the Water Environment Regulations and Conservation of Habitats and Species Regulations already experience high input levels of nitrogen and phosphorus into the water environment.

The planning concern relates to future developments increasing the levels of nitrogen and phosphorus discharged into these water courses, contributing to eutrophication which has significant adverse effects on wildlife and habitats.

Tightening of environmental regulations through recent case law has resulted in Natural England producing guidance and a methodology for achieving nutrient neutrality for new developments. Natural England have also been more visible in their opposition to developments where they feel nutrient neutrality has not been considered or demonstrated.

Calculating Nutrient Neutrality

The revised guidance issued by Natural England in June 2020 sets out the methodology to calculate the net nutrient impact on catchments by calculating the load generated by the development and the residual non-built land use, offsetting any nutrient impact from the current land use.

The Natural England guidance provides different methodology for calculating nutrient neutrality in cases where the wastewater generated by the new development will be discharged to sewer network or treated on the development site by a dedicated treatment plant.

Larger greenfield sites, which have sufficient land being taken out of agricultural use to off-set the anticipated nutrient discharges generated from the proposed development may find that nutrient neutrality can be achieved relatively easily.

There are however many development sites where nutrient neutrality is marginal or difficult to achieve influenced by multiple and sometimes conflicting considerations, including the previous land use, development size, consented discharge at the treatment works or efficiency of any on site treatment solution, these can all become significant factors in determining the viability of a project in achieving planning consent.

Te-Tech Process Solutions have experience helping clients with the evaluation of these factors but more importantly through the delivery of on-site treatment solutions with high Nitrate and Phosphorus removal efficiency, to help achieve overall nutrient neutrality or reduce the surplus load to be off-set through alternative mitigation measures.

Mitigation

Mitigation schemes have and continue to be slow to emerge and those that are available are in high demand with a significant time and cost implication. The available schemes are generally aimed at developers with no agricultural land to offer as direct mitigation. These schemes usually involve payment to third parties who use the funds to secure agricultural land to take it out of agricultural land use, thereby reducing the nitrogen impact on the catchment.

Examples of this approach include wildlife trusts who have established mitigation sites in areas affected and operate on a credit system where developers purchase credits to offset the surplus total nitrogen levels against the reductions generated at the mitigation sites. Local authorities are also looking to generate or trade credits to fund initiatives such as improvements in social housing water efficiency, again to reduce the nitrate impacts on the catchment, but these are seen as a short-term fix until a more established trading platform is available.

In the meantime, it is important to explore opportunities including effective on-site treatment such as the te-cycTM process to help achieve nitrate neutrality or at least minimise any surplus nitrates that need to be off-set through any alternative mitigation.

Te-Tech Process Solutions

Te-Tech Process Solutions are able to provide an efficient, sustainable and cost effective solution for biological nutrient removal, to achieve stringent N and P consent standards.

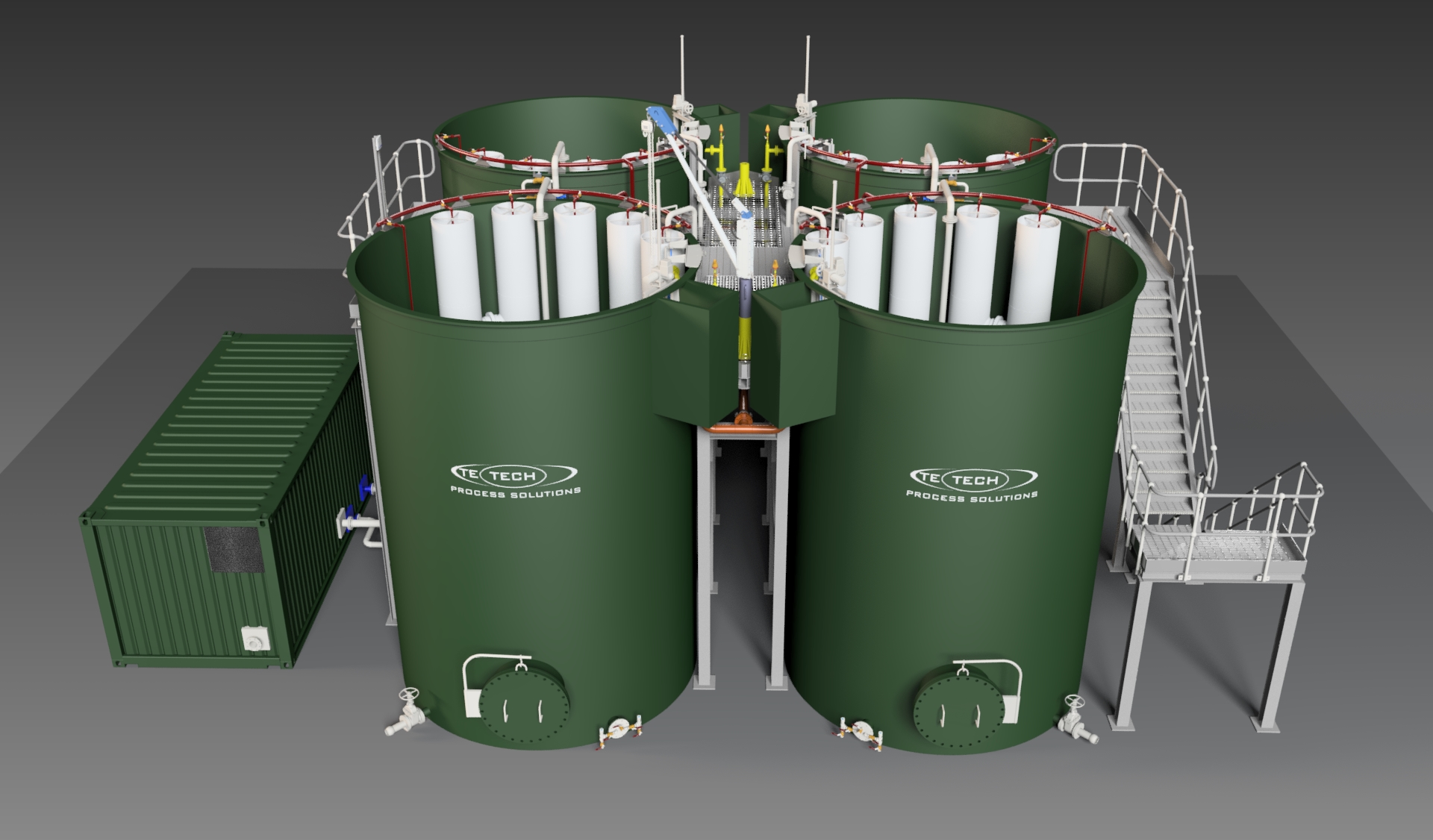

The te-cycTM process, with over 500 reference plants around the world, is at the forefront of biological Nitrate and Phosphorus removal, an enhanced biological treatment process for effective nutrient removal and sludge stabilisation. te-cycTM is the ideal solution for commercial clients seeking to achieve Nitrate Neutrality on new developments and for municipal and industrial clients who require enhanced biological Nitrogen and Phosphorus removal to achieve tightening consent standards.

The te-cycTM process is a cyclic activated sludge process achieving simultaneous nitrification, denitrification and biological P removal. The te-cycTM process is an advancement on conventional wastewater treatment technologies providing enhanced treatment with low chemical and energy consumption and a small overall footprint compared to traditional activated sludge (AS), sequencing batch reactors (SBRs) or granular sludge processes.

The te-cycTM process incorporates an anaerobic selector zone, which suppresses the growth of bacteria that cause sludge bulking and includes internal recycling of the biomass to the main reactor zone to create the formation of ‘macroflocs’.

In the te-cycTM configuration these larger macroflocs form an internal anoxic zone and external aerobic zone and contain polyphosphate accumulating organisms or PAO’s. On the macrofloc surface, bacteria act to convert ammonia to nitrate whilst the PAO's take up phosphorus from the surrounding liquid. Inside the macrofloc, anaerobic bacteria convert the nitrate to nitrogen gas, which escapes harmlessly to atmosphere.

These macroflocs promote enhanced biological removal and very low sludge volume indices and the simultaneous carbon oxidation and nitrification / denitrification in one basin enables shorter cycle times and eliminates the need for a separate denitrification treatment stage. The te-cycTM process provides enhanced N and P removal to achieve more stringent effluent values without the need for an additional solids removal treatment stage.

The te-cycTM process also incorporates advance process control by means of OUR (Oxygen Uptake Rate). The OUR real time control (RTC) system determines the time and intensity of aeration according to the degree of pollution in the wastewater, which results in economic operation of the plant and reduced operational costs.

The te-cycTM Technology is a simple, efficient, low operational cost solution providing effective nutrient removal, enhanced biological treatment and sludge stabilisation for municipal, industrial and commercial wastewater treatment applications.

Modular Treatment Solutions

The te-cycTM process is a simple, efficient, low operational cost solution available as a bespoke design in concrete tanks or in a range of standard off site manufactured modular units to suit different sizes and applications.

The standard modular units come as a complete ‘plug and play’ system including aeration blowers, chemical dosing and local control panels for automated operation. If required Te-Tech can also provide a full end to end solution including inlet works and screening and any subsequent sludge storage, treatment or disposal stages.

Modular solutions for small to medium size developments can be provided as above or below ground installations where the aesthetic impact is a particular consideration.

Larger sites can be catered for with multiple units or streams particularly where there may be seasonal variations in flow and load or alternatively where operational flexibility is required or where flows may be phased or incremental as developments progress.

Te-Tech can also provide larger standard cylindrical modular units for higher flow rates which again can be provided in multiple streams for operational flexibility or phased flow and load increments.